Your Guide to Assembly

NASA’s Europa Clipper spacecraft was designed to determine if Jupiter’s moon Europa could support life below its icy surface. The main body of Europa Clipper is as large as a passenger van, and with its solar arrays deployed, it is long enough to span a basketball court – more than 100 feet (30 meters). Nearly every detail of the spacecraft was handcrafted to enable the acquisition of this unprecedented science.

Here’s how Europa Clipper was assembled.

Hardware Development

Hardware Arrival

Spacecraft Assembly

Environmental Testing

Final Checkouts & Shipment to Launch Site

Launch

Step 1: Hardware DevelopmentStep 1: Hardware Development

Hardware for Europa Clipper was developed at JPL and at partner institutions and contractor facilities across the United States and Europe. This includes the nine science instruments and other spacecraft components, such as the propulsion module, radio frequency module, solar arrays, star trackers, electronics vault, and more. The instruments and components were developed, tested, and shipped to JPL.

Step 2: Hardware ArrivalStep 2: Hardware Arrival

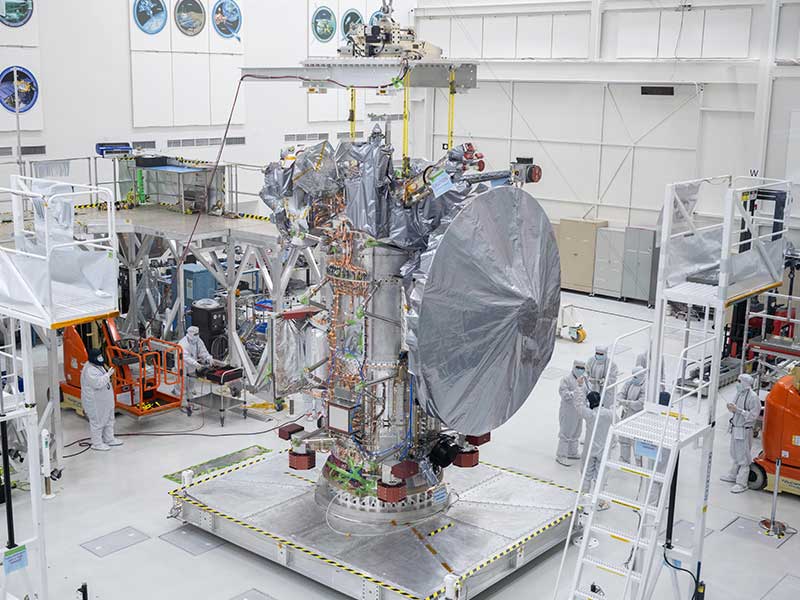

The start of this second phase marked the official start of Assembly, Test, and Launch Operations, or ATLO. Engineers prepared the workspaces they needed to assemble and test Europa Clipper hardware at JPL. They made laboratory spaces ready, including “clean rooms”—spacecraft assembly facilities where dust and static electricity are kept at extremely low levels because they can interfere with or damage spacecraft hardware. These clean rooms also help us prevent the contamination of worlds relevant to the search for life by microbes from Earth.

Instruments and other spacecraft hardware arrived at JPL. Electrical support equipment was brought online, mechanical cabling was put in place, and instrumentation testing procedures worked through. Spacecraft instruments and subsystems were tested at the component level, and had not yet been assembled into their final configuration.

Step 3: Spacecraft AssemblyStep 3: Spacecraft Assembly

Europa Clipper finally began to be assembled into a spacecraft. Hardware that had already arrived, was tested, and stacked to create the spacecraft. While the second phase of ATLO focused on integration and testing prior to assembly, this third step focused on system-level tests of the assembled configuration, including the software systems for flight.

Step 4: Environmental TestingStep 4: Environmental Testing

To reach Europa, the spacecraft must survive liftoff, the heat of the Sun, the cold of space, micrometeorites, and the radiation environment of Jupiter. Tests were conducted to demonstrate that the spacecraft can survive the environments it will experience in flight. That included vibration tests—ensuring Europa Clipper and its components can handle the stress and shaking during launch—and placing the spacecraft in a vacuum chamber as well as a space-Sun simulator. Many of these tests took place in special buildings designed for environmental testing at JPL.

Step 5: Final Checkouts and Shipment to Launch SiteStep 5: Final Checkouts and Shipment to Launch Site

After environmental tests, Europa Clipper was brought back to its assembly facilities for a thorough checkout, to make sure everything was still working correctly. This phase included some disassembly—for example, the high-gain antenna and solar arrays were removed and crated separately. Support equipment for launch also was shipped. Some was transported by truck, while other components were flown to the launch site.

Step 6: LaunchStep 6: Launch

Europa Clipper will launch from Kennedy Space Center (KSC) in Florida on Oct. 10, 2024. The arrival of the spacecraft and associated equipment at KSC marked the start of the final phase of ATLO. The support equipment was unpacked, and the spacecraft was reassembled. Final checkouts were performed, the spacecraft was fueled, and then encapsulated in its fairings. Soon, the spacecraft will be mated with its launch vehicle, a Space X Falcon Heavy rocket. The rocket will roll out to the launchpad. The countdown and launch mark the final steps of ATLO.

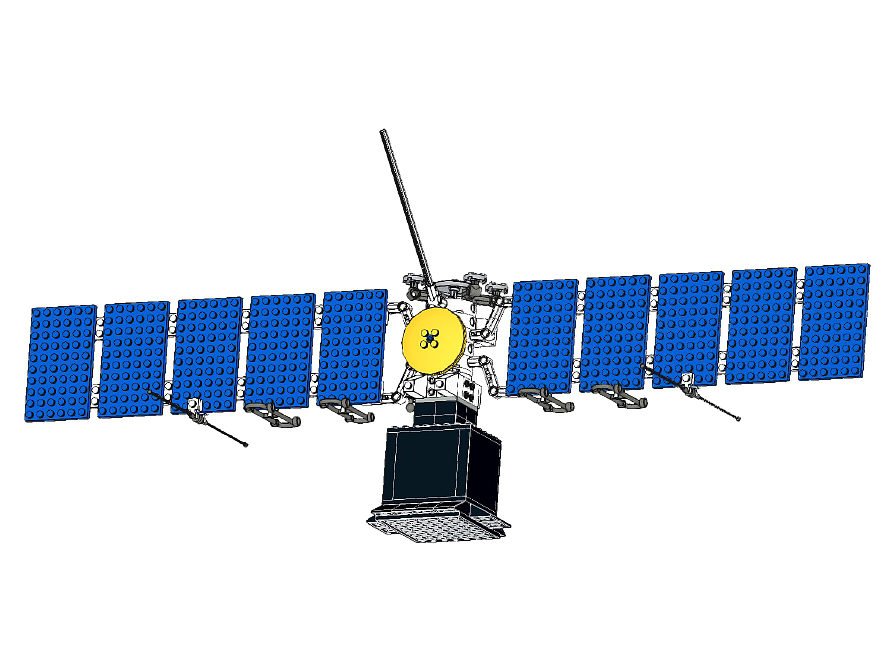

Get Involved: Build Your Own Spacecraft

Want to learn more about the Europa Clipper spacecraft? Build your own version of Europa Clipper at home! Snap a photo of your model and share it on social media using the hashtag #EuropaClipper.

-

Europa Clipper’s paper model is appropriate for students in grades 5+. Download the kit here.

-

Build a 1/48th scale model of the Europa Clipper spacecraft using toy bricks. Download the instructions here.

-

Create your own 3D printed model of the Europa Clipper spacecraft. Download the file here.